Process Control Systems

The PLC systems offered can feature single and redundant configurations for CPU, communication cards, I/O and power supply.

The Unit Control Panel designed by SEID are suitable for various types of packages like: air or process gas rotating equipments, filters, dryers, nitrogen generators, refrigerating packages, HIPPS and pump skids.

Each Unit Control Panel is designed in accordance with customer’s specification and in compliance with standard and norms as: IEC (International), CE (Europe), UL/CSA (USA and Canada), EAC (Eurasian Economic Union (EAEU)), etc...

All systems are designed and programmed by our engineering division and assembled by the production division.

Our products can be integrated in all major control systems as a unique combination of hardware and software with a strong cybersecurity component. This enables dynamic and fail-safe control of entire packaged equipment increasing productivity and profitability.

Before delivery, all systems produced by our Company are fully tested following demanding Factory Acceptance Test (FAT) procedures, as previously agreed with the customer and the enduser.

Compressor Unit Control Panel (UL certified)

The Compressor Unit Control Panels are designed in accordance with the customer's requirements and regulation applied to the final destination.

SEID is certified to design and provide Unit Control Panels with CE, EAC, UL/CSA labels.

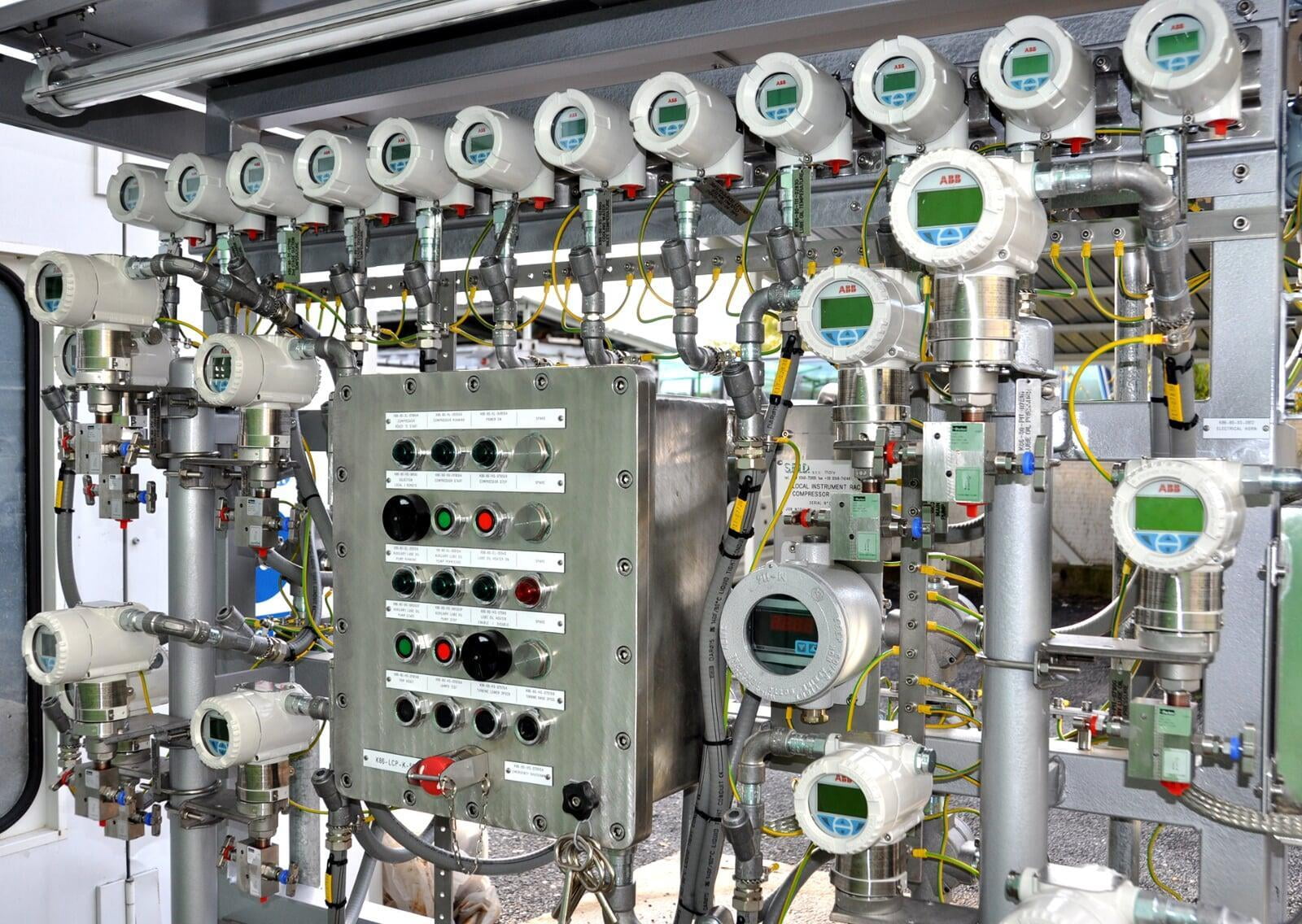

Field electrical equipments

Set-up of packaged equipment using state-of-the art technology.

Installations are carried out based upon international standards, following sector norms and customer specifications.

- Junction Boxes

- Local Pushbutton Station

- Instrument Rack and Gauge Board Panel

- Field instrumentation SMART HART or Fieldbus Foundation

- Instrument cabling with specific cables or personalized conduit solutions